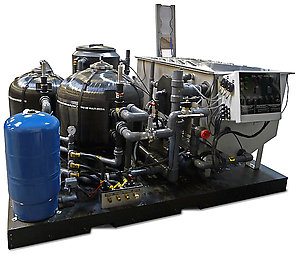

Advanced Wash-Water Recycle Systems WLP-40 Series

WLP-40 Series

Separates oil, water and solids.

Mi-T-M's recycle systems are designed to remove free hydrocarbons and filter the water to be sent back through a pressure washer. The systems come standard with pH and ORP injection. All systems are designed for corrosion-resistance by using stainless-steel tanks.

The WLP Series recycle systems combine enhanced design with state-of-the-art technology to offer:

·Quality recycled wash-water without common odor problems

·Easy operation and maintenance

·CSA approved control panel which meets the requirements of the US and Canadian standards for an Industrial Control Panel

·Easily accessible pumps

·Poly skid is constructed of hardened polymer to be non-corrosive, it can also be easily lifted and moved with a forklift from all four sides

The WLP Series is perfect for the following applications:

·Rental yards

·Heavy equipment dealers

·Trucking facilities

·Truck rental fleets

·Diesel repair facilities

·Forklift washing operations

·Aircraft maintenance and restoration

·Shipyards

·Municipalities/State DOTs

·Oil fields

·Engine rebuilders and manufacturers

·Military bases

Components:

·CSA listed NEMA-4 rated corrosion-proof control panel for safe and reliable operation

·Hose connectors are designed for easy accessibility and quick installation, the connectors are clearly marked

·Pumps are easily accessible

·1.0 HP surface mount sump pump

·Advanced oil/water/solids separator for easy oil separation

·ORP controller measures and injects a germicide to control odor

·pH controller keeps water at the appropriate pH level

·Oil skimmer/decanter removes oil from the surface

·Activated carbon filter

·Pressurized container to hold treated water

Models Available:

WLP-40-0M10 230V, 1Ø, 30.0A 600 sq. ft. cartridge filter

(2) 96in.x60in.x60in. Dimensions (LxWxH) 3,200 lb. ship weight

WLP-40AB-0M10* 230V, 1Ø, 30.0A 60-100 PSI air required

84in.x108in.x60in. Dimensions (LxWxH) 3,100 lb. ship weight

WLP-40AB-0M30* 230V, 3Ø, 17.0A 60-100 PSI air required

84in.x108in.x60in. Dimensions (LxWxH) 3,100 lb. ship weight

Mi-T-M Corporation recommends the use of AC1-HE02-05M1 air compressor for use with the auto backwash models. See product page for more information.

Once equipment is washed, the untreated wash-water flows into your pit system. A proper pit system for your application is the first step in proper wash-water treatment, and a critical element in any wash-water recycle system. See our In-ground Fiberglass Pit System for more information or contact Mi-T-M Corporation or your local distributor to determine the pit system configuration that works best with your application.

*Auto-backwash models (air required 60 to 100-PSI) - Water enters through the bottom of the filter and is forced upward through the filter media when the “auto-backwash” solenoid is energized. This creates a “fluff” effect on the media which flushes out particles and returns them back to the pit via the drain line. This helps prevent “wormholes” in the media itself.

230/208/460V 3-phase available on all models as options.

Specifications

| Flow Rate | 0-40 GPM |

| Media Filter (Custom Mix) | 900 lb. |

| Carbon Filter (degassed) | 165 lb. |

Weights & Dimensions

| Net Weight | 0.00 lbs. |

| Shipping Weight | 0.00 lbs. |

| Length | 0.00 in. |

| Width | 0.00 in. |

| Height | 0.00 in. |

Replacement Air Filter AT-4007

Moisture trapping replacement filter